Isahluli seMagnetic

Kukho iiminerali ezininzi ezinokwahlulwa yi-magnetite, i-limonite, i-hematite, i-manganese siderite, i-ilmenite, i-wolframite, i-manganese ore, i-manganese carbonate ore, i-manganese ore, i-ore ye-manganese, i-ore ye-iron, i-kaolin, i-ore yomhlaba enqabileyo, njl., enokuthi ihlukaniswe yi-separator magnetic.

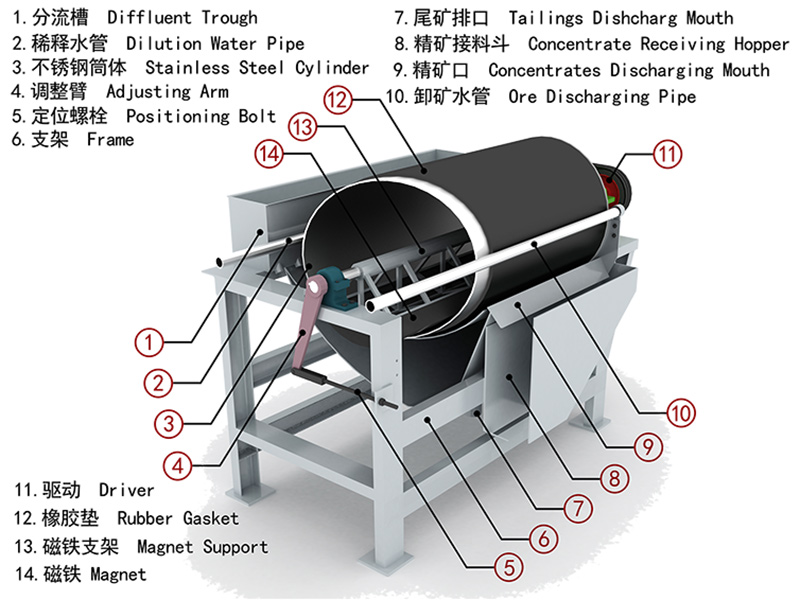

Umgaqo wokuSebenza

Ipompo ingena kwindawo yemigodi yeseli nangona ibhokisi ye-ore inamandla okuhamba kwamanzi. Amasuntswana emagnethi enza ibhola yemagnethi okanye unxibelelwano namandla omhlaba wemagnethi. Ibhola yemagnethi kunye noqhagamshelo zifunxwa kwigubu ngelixa zisiya kwicala lemagnethi ngamandla wemagnethi. Xa ibhola yemagnethi kunye noqhakamshelwano lujikeleza kunye negubu elishukumayo, ngenxa yokushiyana kwepolarity kunye nokuzanyazanyiswa kwemagnethi, i-ganggue kunye nezinye intsimbi ekrwada engeyiyo imagnethi exutywe kwibhola yemagnethi kunye nonxibelelano iye phantsi, ngelixa ibhola yemagnethi kunye nonxibelelwano zifunxwa kumphezulu wegubu. Ezi zizinto zogxininiso esizidingayo. Ugxininiso luza kwintsimi apho imagnethi iyeyona ibuthathaka kunye negubu elijikelezayo. Emva koko bawela ukuze bagxininise indawo yokuhamba kwamanzi. Kodwa i-roller yamagnetic epheleleyo isebenzisa i-brush roll ukukhupha ii-ores. Ekugqibeleni, iiminerali ezingezizo ezinomagnetic okanye ezibuthathaka zikhutshwa kwiseli ngokutyebileyo.

Iinzuzo zeMveliso

1. Isiphumo esihle sokwahlukana:Lo matshini wamkela inkqubo yemagnethi eguqukayo. Iintsimbi ezikrwada ziyatyibilika, zishukume kwaye ziqengqeleke kumphezulu wegubu, kwaye akukho zintsimbi ezincamathelayo kwigubu, elinceda ukwahlula ore ezahlukeneyo. Ibakala lingaphuculwa amaxesha angama-1-4 kwinkqubo yokuqala yokwahlukana, kwaye ibakala linokufikelela kuma-60% kwinkqubo yokwahlula kakuhle.

2. Umthamo omkhulu:Ngokusebenzisa uhlobo olusongelweyo oluvulekileyo lwenkqubo yamagnetic, izixhobo azibambeleli kunye kwaye isenzeko sokuthintela sinokuphetshwa, esikhokelela kumthamo omkhulu. Umthamo wokutyisa wesahluli sombane ozibuthe ubuncinane ziitoni ezingama-50. Kwaye oomatshini banokudityaniswa ukuze basetyenziswe ukuze kuphuculwe umthamo.

3. Usetyenziso olubanzi:Olu hlobo lwesahluli samagnetic lunokwahlulwa lube ziindidi ezi-4, iintlobo ezingaphezu kwama-20 kunye neemodeli, ezinokuhlangabezana neemfuno zentsimbi, isanti yomlambo, ii-tailings, slags, intsimbi yentsimbi, i-sulfate slag, izinto zokusila, i-refractory, i-plating, i-rubber, amashishini okutya kunye njl. Ezinye zazo zineenjongo ezininzi.

Iinkcukacha

| odel | CTB612 | CTB618 | CTB7512 | CTB7518 | CTB918 | CTB924 | CTB1018 | CTB1024 | |

| Ububanzi (mm) | Φ600 | Φ600 | Φ750 | Φ750 | Φ900 | Φ900 | Φ1050 | Φ1050 | |

| Ubude (mm) | 1200 | 1800 | 1200 | 1800 | 1800 | 2400 | 1800 | 2400 | |

| Isantya (r/min) | 35 | 35 | 35 | 35 | 20 | 20 | 20 | 20 | |

| Gauss | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | |

| Ubungakanani bokutya (mm) | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | |

| Uxinzelelo lokutya(%) | 20-25 | 20-25 | 20-25 | 20-25 | 25-35 | 25-35 | 25-35 | 25-35 | |

| Ukukhutshwa komsebenzi (mm) | 30-40 | 30-40 | 30-40 | 30-40 | 45-75 | 45-75 | 45-75 | 45-75 | |

| Umthamo | intsimbi eyomileyo (t/h) | 10-15 | 15-20 | 15-20 | 30-35 | 35-50 | 40-60 | 50-100 | 70-130 |

| intlama (m3/h) | 10-15 | 15-20 | 15-20 | 30-35 | 100-150 | 120-180 | 170-120 | 200-300 | |

| Amandla (kw) | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 4 | 5.5 | |

| Ubunzima (kg) | 1200 | 1500 | 1830 | 2045 | 3500 | 4000 | 4095 | 5071 | |

| Umyinge jikelele (mm) | 2280×1300 ×1250 | 2280×1300 ×1250 | 2256×1965 ×1500 | 2280×1965 ×1500 | 3000×1500 ×1500 | 3600×1500 ×1500 | 3440×2220 ×1830 | 3976×2250 ×1830 | |